HOW DIFFERENT IS OLEAMIDE AND ERUCAMIDE SLIP ADDITIVE?

Why use slip additive?

Lubricant is a commonly used substance in the field of film production and partly used in the production of filamentous products (filament, yarn, ...).

In the process of processing polymer materials, internal friction arises from two sources:

- Friction between polymer and polymer (i.e. between molecules), this friction is called internal friction.

- Friction between the polymer and the device wall: friction between the polymer and the screw surface, the forming die surface, the guide system surface, etc. These frictions are called external friction.

The role of the lubricant is to reduce the aforementioned internal and external friction, in order to help minimize the harmful effects arising during the machining process:

- Large energy loss, increased processing cost

- Uncontrolled energy generation, causing loss of quality control.

- Damage to the molecular chain of the polymer (ie break the molecular chain), reduce the properties of the plastic

Working principle of slip additives

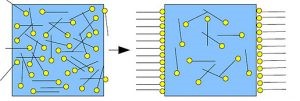

Smoothing agents such as oleamide and erucamide are usually low molecular size, low coefficient of friction and their melting point is also low. They easily migrate to the outer surface of the product immediately after machining and form a favorable gliding layer on the surface of the product, so that the product slides smoothly on the contact surfaces.

For the packaging industry, which often uses Polyethylene and Polypropylene resins, the lubricants are usually waxes, such as ecuramide, ethylene Bis(stearamide), ...

It should be noted that the thickener may affect the printing on the product.

PRINCIPLE OF OPERATION

The principle of operation of the lubricant in the polymer blend is a highly mobile component with a low coefficient of sliding friction. In the machined condition, they act as a flexible buffer between the molecules and between the polymer and the device wall.

- To reduce internal friction, they must have a large enough affinity for the polymer molecule to be able to penetrate the spherical structures (Spherulites) and release their arrangement. They form a cushion between polymer molecules or between spherical structures, allowing them to slide more smoothly.

- In order to reduce external friction, they must be able to rapidly migrate to the surface of the polymer and to flow with the polymer. They also have a binding affinity for the metal surface, and soon coat the metal surface in a low-friction cushion.

Distinguishing Oleamide and Erucamide

In essence, these two types of smoothing powder have the same uses and application properties. However, for each type will have the same intended use. Oleamide powder, with a cheaper price, is suitable for producing finished products such as blown films, plastic bags, etc. And Erucamide powder is more advanced and has a higher price, suitable for enterprises producing plastic additives.

Product's name | OLEAMIDE (other names: FinaWax O; OleWax; Crodamide; Emerest) | ERUCAMIDE (other names: FinaWax E; Emoslip E; EruWax;...) |

Concept | Oleamide is a product of the amide process of fatty acids in nature. Oleamide has many applications in a number of fields, such as: porous structure stabilizer, waterproofing for paper, color dispersion for textile industry, etc. In the field of plastic production, Oleamide is mainly used as a thickening agent. smooth, mold-proof, scratch-reducing, color dispersion, processing aid, etc.

| Erucamide helps to create a smooth, glossy (easy to open the mouth for Packaging), specialized for blowing grease bags, in addition, it also helps to improve transparency, helps reduce friction (anti-scratch) for ropes, processing aids, easy to separate mold for injection molding products. |

CTHH | C18H35NO | C22H43NO |

Melting temperature: | 70 oC | 80 – 85 oC |

Mechanism of action | Oleamide is a wax with a non-polar linear structure and a polar amide functional group, so the molecule is polypolar. Oleamide has a relatively low molecular weight, a flexible chain, so it tends to migrate to the outside of the resin stream, creating a number of effects: reducing the coefficient of friction (increasing the smoothness), reducing adhesion to the needle wall. type, … | Erucamide is a wax with a structure consisting of a non-polar straight chain and a polar amide functional group, so the molecule is polypolar. Erucamide has a relatively low molecular weight, a flexible chain, so it tends to migrate to the outside of the resin stream, creating a number of effects: reducing the coefficient of friction (increasing the smoothness), reducing adhesion to the metal wall type, … |

Benefit | Oleamide improves the flow of the resin, reduces flow defects, helps to reduce the friction of the resin with the device wall. Therefore, Oleamide also reduces energy consumption and equipment wear. Oleamide migrates to the outer surface of the plastic product, reducing the coefficient of surface friction and reducing the adhesion between the plastic and the metal wall. As a result, Oleamide helps to increase the smoothness, ease of mold separation, and reduce scratches to the plastic. Oleamide is also an ingredient that helps to disperse some colors into the plastic. Oleamide also partially improves the gloss of the product | Erucamide improves the flow of the resin, reduces flow defects, helps to reduce the friction of the resin with the device wall. As a result, Erucamide also reduces energy consumption and equipment wear. Erucamide is also an ingredient that helps to disperse some colors into the plastic. Erucamide also partially improves the gloss of the product. |

Application | Film and plastic packaging PE, PP Blowing bags with high smoothness and transparency (commonly called grease bags). | Used for plastic: PE, PP, PET,… Low-friction PVC sheath: power cable Blowing smooth film to pack rubber nuggets, semi-finished rubber products separator film. Blowing anti-snow tarpaulins for cold countries. |

Usage rate | 0.05 to 0.12% (ie 50g to 120g for 100kg of resin mix) | 0.05 to 0.12% (ie 50g to 120g for 100kg of resin mix) |

Packaging | 25kg/bag | 25kg/bag |

SUNRISE COLOURS VIETNAM CO., LTD

Add: CT2A Building, Gelexia Riverside Apartment, 885 Tam Trinh Street, Yen So Ward, Hoang Mai District, Hanoi City.

Phone: +84 986998350 Fax: 0084 02436452586

Moblie/What'sapp/Wechat: 84 986998350

Email: sales3@sunrisecolour.com

Website: http://sunrisecolour.com

Related posts

.png)