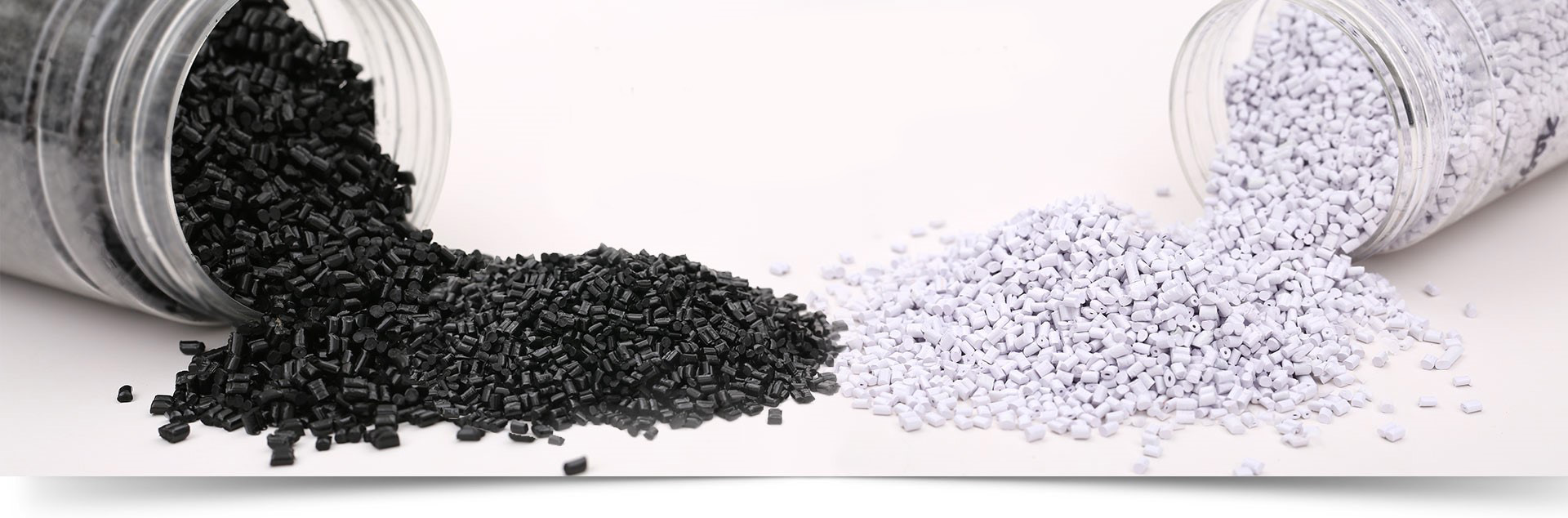

BLACK MASTERBATCH - WHITE MASTERBATCH - WHAT MUST KNOW ?

Plastic is widely used in industrial and consumer products. There are almost no empty areas left for the polymer to yet touch. There are many reasons for this, such as the versatility of polymers that can mold into any shape. That is why manufacturers can create a wide variety of consumer products in a variety of shapes and colors ...

I. MASTERBATCH IN CONSUMMING PRODUCT

Masterbatch nowaday are being used and applied widely in plastic industry, due to its features, benefit it brings to plastic production.

Any raw polymer undergoes multiple treatment steps before the final consumer plastic is made. Furthermore, natural polymers gain new properties and features according to the needs of market consumers. That is possible with the addition of a unique chemical compound called a masterbatch.

Here are the top masterbatch chemical compounds used in the plastic manufacturing process:

- Color masterbatch

- Plasti additives

Masterbatch is solid or liquid materials that can transmit colors and change the properties of finished products. In addition, masterbatch works on many fronts to develop a resin that is loved by consumers with desirable properties such as toughness, smoothness, gloss and other features.

- Color masterbatch

In color masterbatch, colorant manufacturing companies store hundreds of colors in their database. We can make shades like red, blue, chestnut, yellow, black, white, silver and others from them. In this way companies in the plastic processing sector can obtain the desired colors to add to consumer products.

- Plastic Additive

Plastic additive are pellets that are added to the base polymer to ensure dispersion and enhance the properties of the final properties. In addition, the plastic additive can act as an ultraviolet stabilizer, flame retardant, antistatic, slip agent and others. In short, plastic additive are determined based on the physical properties required by a manufacturer on the product.

II. BLACK MASTERBATCH

- What is Black Masterbatch?

Black masterbatch is one of the most widely used colorants in the plastics industry today. Made from black carbon, the grade is determined based on the customer's requirements and manufacturer's needs. It is of a higher quality thanks to the properties of black carbon and the way it is manufactured. In addition, it should have uniform dispersion and concentration levels, determine black intensity, luminance and meet other requirements.

- What are the applications of the black masterbatch?

Black masterbatch are used in many industrial plastic processes. Main applications are in packaging films, pipes, automobiles, compounds, control panels, sprayers, cables and other products. No matter what additives are used, it is necessary to ensure enough blackness and coverage according to the needs of consumers.

In addition to the standard masterbatch, the use of a specially designed black masterbatch helps to create a darker and brighter tone in the plastic as needed.

Let's take a look at the application industries:

- Woven bag / Raffia

- Nonwoven

- Film blowing

- Blow molding

- Injection molding

- HDPE pipes

III. WHITE MASTERBATCH

- What is white masterbatch?

The white masterbatch is super fine and super white Titanium Dioxide, which has many different ingredients. Titanium Dioxide Ti02 load ranges from 20% to 75% depending on consumer requirements. Quality depends on the filler used during the manufacturing stage, but concentration is of primary importance.

- Advantages - disadvantages of white masterbatch?

Advantages of a quality white masterbatch in plastic processing:

- Provides excellent dispersion.

- Enhances the opacity and whiteness of the product.

- Provides resistance to ultraviolet rays

- Comes with high thermal stability under treatment conditions reducing TiO2 aggregation.

- Anti-vibration for woven bags

- Improve the heat resistance of the product.

- Resistant to weather conditions.

- Suitable for application into film production

In addition, it is also suitable for the field of packaging packaging and disposable products. The use of white masterbatch results in better results in film packaging, blow molding, heat forming and other processes.

- Industrial applications

- Used in thick and thin wall processes such as extrusion, blowing, and extrusion.

- For use in single and multi-layered films

- Food packaging application

- Weather resistant application

- Use in high speed machines

- Heat stability.

- Nonwoven

Used in the manufacture of bottles, caps, water tanks, disposable cups and others.

Above is information about black and white plastic resins used in the production and processing of plastic products. To get a quality plastic product, you need to have a good quality input source of masterbatch. Sunrise Colours Vietnam is proud to be the leading supplier of color masterbatch in Vietnam due to the best raw materials, the most modern production equipment and a team of experienced professional engineers.

Contact us today for consult and quotation.

SUNRISE COLOURS VIETNAM CO., LTD

Add: CT2A Building, Gelexia Riverside Apartment, 885 Tam Trinh Street, Yen So Ward, Hoang Mai District, Hanoi City.

Phone: +84 986998350 Fax: 0084 02436452586

Moblie/What'sapp/Wechat: 84 986998350

Email: sales3@sunrisecolour.com

Website: http://sunrisecolour.com

Related posts

.png)